Wires & Cables

SAISONIC produces a wide range of electrical wires and power cables for different applications. Our cables come in various conductor sizes, insulation types, voltage ratings, and sheath materials. This allows us to provide clients with a diverse product range and meet different electrical and physical requirements.

We adhere to international standards and design our products to withstand harsh environment conditions, including mechanical stress, abrasion, oil, chemicals, and weather exposure. Our solutions are durable, cost-effective and can suitable for outdoor use without compromising quality. We design, manufacture, and test our products under one roof, providing clients with complete, one-stop cable solutions.

We have a professional materials laboratory that can develop and optimize insulation and sheath materials such as PVC, PE, PP, TPE, PUR, silicone, and PTFE to meet different application needs, including flexibility, heat resistance, and fire safety. Careful material selection and development ensure high-quality, high-performance cables. We use high-purity oxygen-free copper rods, precisely drawn and annealed to maintain good conductivity, strength, and flexibility, ensuring low resistance and reliable signal transmission. High-purity copper reduces electrical losses, while precise manufacturing guarantees mechanical strength and reliable performance, particularly for data and power transmission.

Fully digital extrusion lines maintain uniform insulation and sheath thickness and concentricity, ensuring stable performance and long-lasting durability. Digital control ensures high precision that manual processes cannot reliably achieve. Fast braiding machines produce metal shields with high coverage to protect against electromagnetic interference (EMI), crucial for sensitive electronics and data communication applications. We are also skilled in foil shielding techniques and combined shielding designs, offering additional flexibility. For data and multi-core cables, we carefully control cable twist and lay lengths to manage capacitance, impedance, and crosstalk, ensuring clear and reliable signals.

-

Online Real-Time Monitoring

To ensure consistent cable dimensions, we use in-line diameter gauges and eccentricity testers during extrusion. These instruments monitor and control the cable’s outer diameter and concentricity in real time, enabling consistent process quality control (SPC).

-

Full Certification and Compliance

Our products meet international safety and environmental standards, including UL, CSA, VDE, CE, CCC, RoHS, REACH, and other relevant directives. This ensures that our products are ready for global market applications.

-

Comprehensive Laboratory Testing

- Our industry-leading lab conducts electrical, mechanical, environmental, and fire safety tests.

- Electrical testing includes continuity, high-voltage (HIPOT) tests, insulation resistance, capacitance, and impedance measurements.

- Mechanical tests cover tensile strength, elongation, abrasion resistance, bending life, and repeated twisting tests.

- Environmental testing includes high/low temperature cycling, thermal aging, oil resistance, acid/alkali resistance, and UV aging tests.

- Fire performance testing includes flame retardancy, bundle burning, and low-smoke halogen-free tests (halogen content, pH, conductivity).

SAISONIC also offers custom cable and wire solutions. Our customization services include:

- Conductor types: stranded or solid wires

- Conductor materials: copper, aluminum, silver, and other materials

- Insulation materials: PVC, XLPE, PTFE, silicone, or any other material

- Diameter range: standard from 4/0 AWG to 40 AWG. Customizable to your requirements.

When submitting a request, please provide the following information. With this information, we will be able to quickly find the right cable model and provide accurate pricing.

-

Conductor Material

Conductor MaterialThis is the first step in your project, as it determines the key properties of the entire cable. Here’s a quick overview of the conductor materials: stranded conductors are flexible; solid conductors keep their shape for safer connections; pure annealed copper is easy to work with; tinned copper resists corrosion; and aluminum is lightweight.

-

- PVC (Polyvinyl Chloride): a popular thermoplastic insulation, tough and chemically resistant.

- XLPE (Cross-Linked Polyethylene): offers excellent mechanical and electrical properties, and as a thermoset material, it does not shrink when cutting or welding wires.

- Synthetic Rubber: wear-resistant, provides high strength and good insulation.

- Fluoropolymers: include PTFE (Polytetrafluoroethylene) and ETFE (Ethylene Tetrafluoroethylene). Both can withstand high temperatures up to 200°C and are resistant to chemicals, oil, and wear.

Insulation Material Requirements

Insulation Material RequirementsWe offer the following insulation material options:

-

Temperature Rating

Temperature RatingCheck the maximum temperature your cable needs to handle. Most wires work up to 80–90°C. For high-temperature applications between 150°C and 200°C, PTFE or ETFE cables are recommended.

-

- UL 1015 cable: 600V max

- UL 1065 cable: 300V max

- UL 3265 XLPE cable: 150V max

Voltage Rating

Voltage RatingCheck the maximum voltage for your cable type:

-

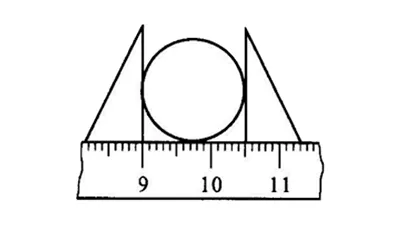

Cable Diameter Requirements

Cable Diameter RequirementsSpecify the cable outer diameter, conductor diameter, and insulation thickness. The easiest way is to tell us the AWG (American Wire Gauge). We offer sizes from AWG 4/0 to AWG 45.

-

Low-voltage cable

Low-voltage cable -

High-voltage cable

High-voltage cable -

THHN wire

THHN wire -

Solar cable / PV cable

Solar cable / PV cable -

Hook-up and lead wire

Hook-up and lead wire -

UL and CSA style cables

UL and CSA style cables -

Power cable

Power cable -

Automotive cable

Automotive cable -

High-temperature Cable & Wire

High-temperature Cable & Wire -

LSZH cable

LSZH cable -

Control cable

Control cable -

Custom cable and wire

Custom cable and wire

Tell us your wiring needs and our experts will help you find the right solution.