SAISONIC was founded in 1992. Over nearly 33 years of steady growth, we have become a leading provider and partner for wire harnesses and cable assembly solutions. Our factory is located in Dongguan, China, covering 8,016 m² of land with more than 30,000 m² of building space. We have a team of over 450 employees, including 7 sales professionals, 10 R&D engineers, 340 operators, 36 quality staff, and more than 60 in management. Our facility includes 10 wire harness production lines and 3 cable assembly lines, producing over 8 million wire harnesses and 600,000 cable assemblies every month. We provide both rapid prototyping and large-scale production, with flexible delivery options to meet your project needs.

SAISONIC holds ISO9001 and ISO14001 certifications for quality and environmental management. Our quality team, which includes IQC, OQC, QC, and other specialists, oversees the entire production process. From raw material purchasing and incoming inspections to storage and final output, we ensure full quality control and manage hazardous substances. We perform process checks, first-piece inspections, and last-piece inspections. Raw materials are stored under controlled temperature and humidity, following the first-in-first-out (FIFO) principle. Our advanced ERP system allows us to track every step of production for both wire harnesses and cable assemblies.

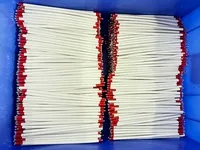

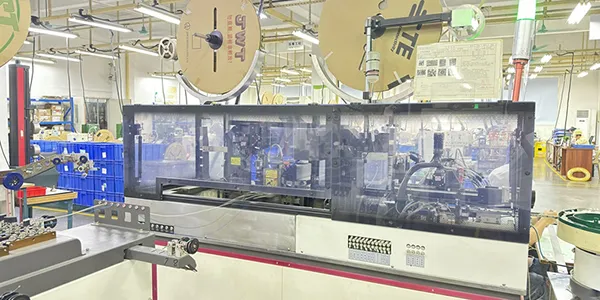

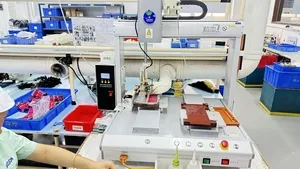

SAISONIC operates 18 fully automatic computerized wire cutting machines. These machines allow setting wire length, diameter, stripping length, and production quantity in the program. They also automatically control wire feeding, cutting, and stripping, with length accuracy within ±0.5 mm, processing thousands of wires per hour.

-

Wire Cutting

-

Wires

Wires

-

Fully Automatic Computerized Wire Cutting Machine

-

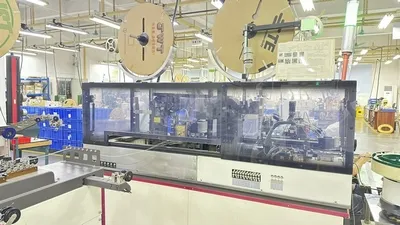

Automatic Wire Cutting Machine

Automatic Wire Cutting Machine

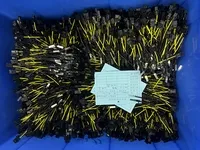

We have 18 machines for automatic stripping, manual stripping, and combined cutting/stripping, capable of handling all types of wire stripping and cutting services.

-

Manual Wire Stripping

-

Automatic Wire Stripping

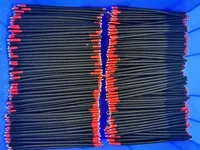

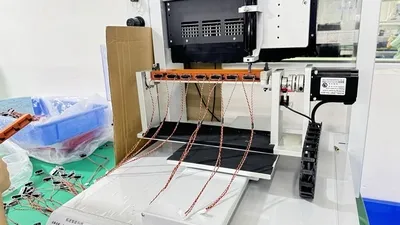

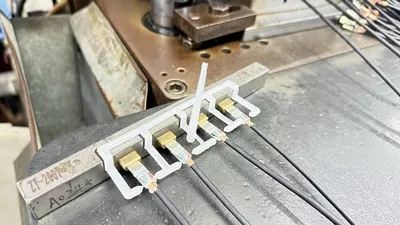

SAISONIC operates 67 crimping machines, including fully automatic (SCM), semi-automatic, and manual units. We serve demanding industries such as automotive, aerospace, medical, consumer electronics, and home appliances. Every crimped product undergoes rigorous quality checks, including tensile testing, crimp height monitoring, and microsection analysis, ensuring that all products meet industry standards.

-

Manual Wire Crimping

-

Automatic Wire Crimping

We use automatic soldering machines, manual soldering, and wave soldering techniques. X-ray inspection is used to make sure there are no cold solder joints, shorts, pinholes, excessive flux, or deformations. This ensures that all custom wire terminations meet your project requirements.

-

Automatic Wire Soldering

-

Automatic Wire Soldering

Automatic Wire Soldering -

Manual Wire Soldering

Manual Wire Soldering -

Manual Wire Soldering

Connector assembly is the final step that brings together all previous processes—cutting, stripping, crimping, and soldering. With strict procedures and multiple quality checks, we guarantee that every wire harness we deliver is fully functional.

-

Manual Terminal Connector Assembly

Manual Terminal Connector Assembly -

Semi-Automatic Terminal Connector Assembly

-

Automatic Terminal Connector Assembly

Includes tape wrapping, cable tie installation, component mounting, assembly, and potting.

-

Wrapping Insulation Tape

Wrapping Insulation Tape -

Cable Ties Installation

Cable Ties Installation -

Assembly Organization

Assembly Organization -

Accessories Installation

Accessories Installation -

Assemblies

Assemblies -

Potting / Glue Dispensing

Potting / Glue Dispensing

Overmolding lowers costs, provides strain relief at cable ends, and extends the service life of cable assemblies. SAISONIC operates 22 injection molding machines, supporting materials like PVC, TPR, TPE, and offering a variety of colors and shapes.

Types of Custom Overmolded Cable Assemblies

- Ferrite cores (single/dual)

- Transition molds (T-mold/Y-mold)

- Audio connectors (banana plug jacks, DC power plug jacks, 3.5 mm stereo plugs)

- Strain relief

- Circular connectors (M8/M12 cables)

- Right-angle molded assemblies

-

Cable Overmolding

Continuity testing ensures all wires are connected properly with resistance ≤ 0.1 Ω. Insulation resistance testing is conducted at 500 VDC, verifying insulation between wires and between wires and the housing meets standards.

-

Cable Hi-Pot Testing (Dielectric Strength Test)

-

Cable Continuity Test

At this step, the overall condition of the harnesses and cable assemblies is inspected: no damage, breaks, or exposed wires; terminals free from oxidation, deformation, or incomplete insertion; connectors clean; wire labels clear and correctly placed. Inspection methods include magnifier checks and X-ray inspection.

-

Inspection with Magnifying Glass

Inspection with Magnifying Glass -

X-ray Inspection

X-ray Inspection -

Appearance Inspection Area

Appearance Inspection Area -

Appearance Check

Appearance Check -

Appearance Check

Appearance Check -

Appearance Check

Appearance Check

After passing all inspections, wire harnesses and cable assemblies are packaged following standard operating procedures (SOP) and stored in the finished goods warehouse until shipment.

-

Cable Assembly Packaging

(Wire Harness and Cable Assembly Testing Equipment)

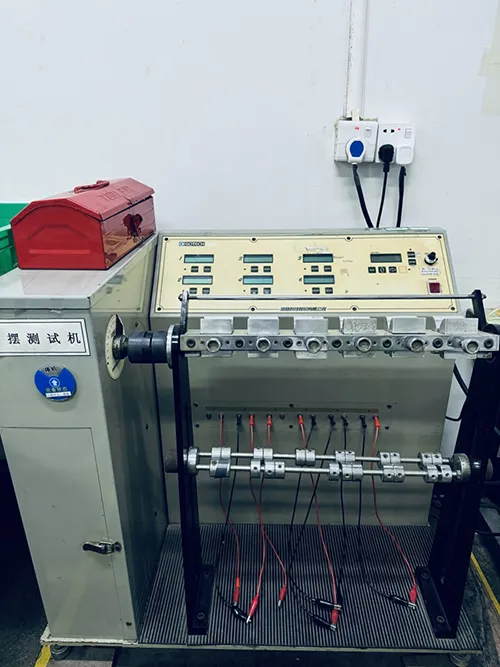

This test simulates mechanical stress such as bending and swinging that wires experience during actual use, assessing their durability and reliability.

-

Test Standards

- IEC 60884-1: For plugs and sockets used in household and similar applications. Test angle: 90°, hanging weight: 1–2 kg (depending on wire cross-section), 10,000 cycles, speed: 60 cycles/min.

- GB/T 2099.1: Equivalent to IEC 60884-1, specifies rated current, voltage, and acceptance criteria (e.g., break rate ≤10%).

- UL817: For power cords; supports 360° bending, weight: 50–500 g, speed: 60 cycles/min.

-

Test Parameters

- Angle Range:

- Standard: 90° (power cords)

- Limit: 180° or 360° (mechanical cables, high-load applications)

- Speed & Cycles:

- Standard test: 60 cycles/min, 10,000 cycles (power cords) or 20,000 cycles (IEC connectors)

- High frequency test: up to 5Hz (360° extreme test)

- Load Conditions:

- Wire cross-section ≥0.75mm² → hanging weight: 2kg

- Wire cross-section <0.75mm² → hanging weight: 1kg

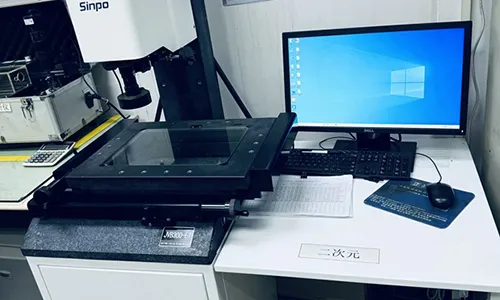

(3D Imaging and Precise Measurement for Crimping)

- Microscope magnification: 0.75× – 4.5×

- Total video magnification: 40–260×

- Zoom ratio: 6.5:1

- Working distance: 100 mm

- Travel range: 250 mm

- 2D mechanical stage with ball-bearing guide, platform size: 180×155×26 mm, moving range: 75×55 mm, glass turntable diameter: 95 mm

- Imaging system: SONY video system (Japan)

- Measurement accuracy: 0.001 mm

- Lighting: Full white LED illumination

Measures the dimensions of parts along X, Y, and Z axes, including height, width, and depth, using coordinate-based technology.

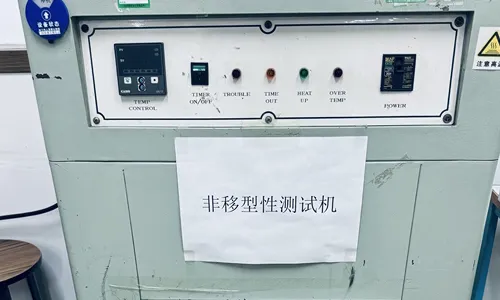

This test follows general standards (e.g., Sony). A 2.5 mm thick test plate (400×400 mm) is used. After placing the sample between two plates at 60 °C for 24 h and applying a 500 g (or 200 g) weight, the test plate is examined visually. No marks or migration indicate a pass.

* “Migration” refers to impressions left on the test plate.

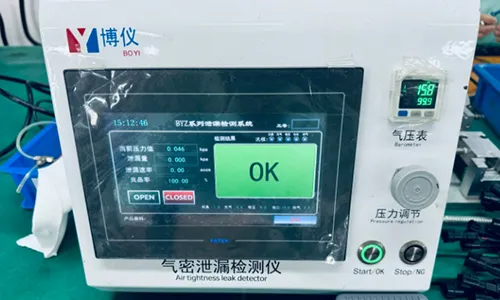

Testing the sealing of wire harnesses to ensure there is no gas leakage that could cause failure. Standards include ISO 6722, JIS D 0203, and ISO 9170-1.

- Continuity Test: applies current to the harness or assembly; measures voltage and current at cable ends to calculate resistance (Ohm’s Law). Compares measured resistance to set values to ensure compliance.

- Insulation Test: applies high voltage between wires and grounding lines; checks current flow to determine if insulation meets standards.

- Hi-Pot Test: applies high voltage for a set time and measures current. If current exceeds preset limits, the harness fails. Measures insulation resistance and displays results.

Uses secondary X-rays emitted when materials are irradiated with high-energy X-rays or gamma rays to determine elemental composition.

Identifies and quantifies chemical substances in components and determines molecular structure and chemical properties. GC separates volatile components, and MS detects and measures them.

Non-destructively examines the internal structure of wire harnesses and cable assemblies to detect hidden defects.

Products comply with international regulations including RoHS, REACH, POPs, CMRT, and EMRT.

-

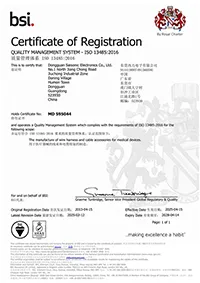

ISO9001 Certification First certified on November 17, 1999

ISO9001 Certification First certified on November 17, 1999 -

ISO14001 Certification First certified on April 15, 2011

ISO14001 Certification First certified on April 15, 2011 -

ISO45001 Certification First certified on March 25, 2020

ISO45001 Certification First certified on March 25, 2020 -

IATF16949 Certification First certified on April 20, 2008

IATF16949 Certification First certified on April 20, 2008 -

SONY Green Partner First certified on July 1, 2010

SONY Green Partner First certified on July 1, 2010 -

ISO13485 2025 MD 595044 First certified on April 15, 2013

ISO13485 2025 MD 595044 First certified on April 15, 2013

Delivering reliable wire harnesses and cable assemblies tailored to your specific wiring needs!