SAISONIC was established in 1992. With 33 years of experience in custom cable processing, we have built long-term, trusted relationships with brands worldwide. We are now actively shaping and leading the industry with our extensive experience in cable assembly manufacturing and professional knowledge. We serve a variety of industries with all types of OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) cable assembly solutions. The company is also a leader in the custom cable industry in China, using advanced manufacturing technologies and equipment. SAISONIC is committed to providing the most precise and cost-efficient solutions to our clients. We can meet your needs, even for the most non-standard and ambitious projects, quickly adapting to your specific requirements.

-

Connector / Housing / Terminal Customization

Connector / Housing / Terminal CustomizationBesides working with customer-specified brands like Harting, Phoenix, FCI, Amphenol, Molex, Aptiv, Tyco, Hirose, Yazaki, and JST, we provide alternative connector solutions.

-

Cable Length Customization

Cable Length CustomizationWe can make cables from just a few centimeters up to tens of meters, exactly according to your drawings and requirements.

-

Wire Conductor Size Customization

Wire Conductor Size CustomizationIn addition to standard AWG 4/0 to AWG 40 sizes, we can produce any non-standard wire diameters you need.

-

Wire Insulation Materials

Wire Insulation MaterialsWe offer a variety of insulation options, including PVC, XLPE, TPU, Teflon, and silicone.

-

Conductor Materials

Conductor MaterialsSolid or stranded conductors, with copper, aluminum, silver, and other materials available.

-

Number of Wire Cores

Number of Wire CoresWhether your design needs 2 cores or more than 60, we can deliver reliable, cost-effective solutions.

-

Custom Color Coding

Custom Color CodingSingle color, multiple colors, stripes, or printed text.

-

Custom Packaging Solutions

Custom Packaging SolutionsPE bags, printed logos, and customized cartons.

-

- Provide original drawings, samples, or concepts

-

- Plan and discuss the project requirements

-

- Provide sample production cost and mass production unit price

-

- Customer approval for sample production

-

- Sample production (typical turnaround: 3–7 days)

-

- Customer confirms the samples

-

- Small-scale trial production followed by full-scale production

Injection molding / strain relief, ferrite core installation, cable branching, tape wrapping, panel mounting, potting, heat-shrink tube installation, and cable tie bundling.

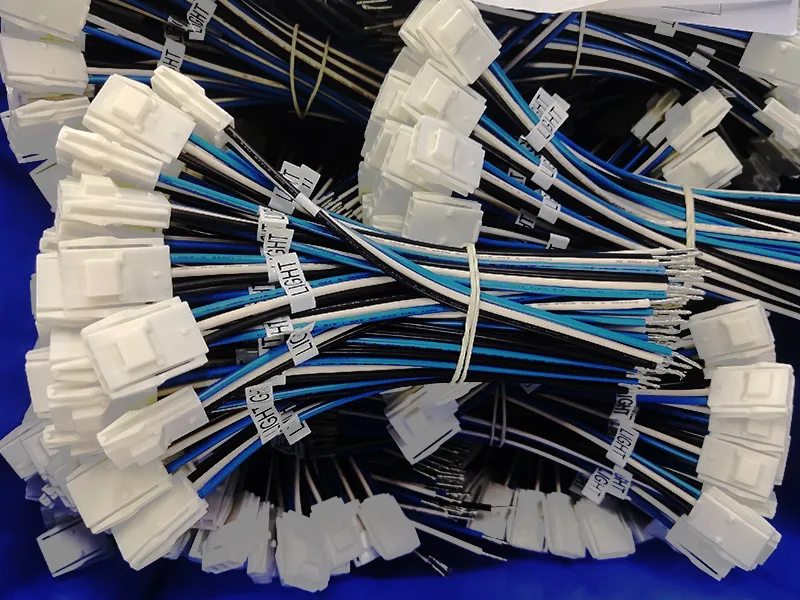

Electrical Cable Assemblies, Coaxial Cable Assemblies, Multi-Conductor Interface Assemblies, Connector-to-Board Assemblies, Power Transmission Assemblies

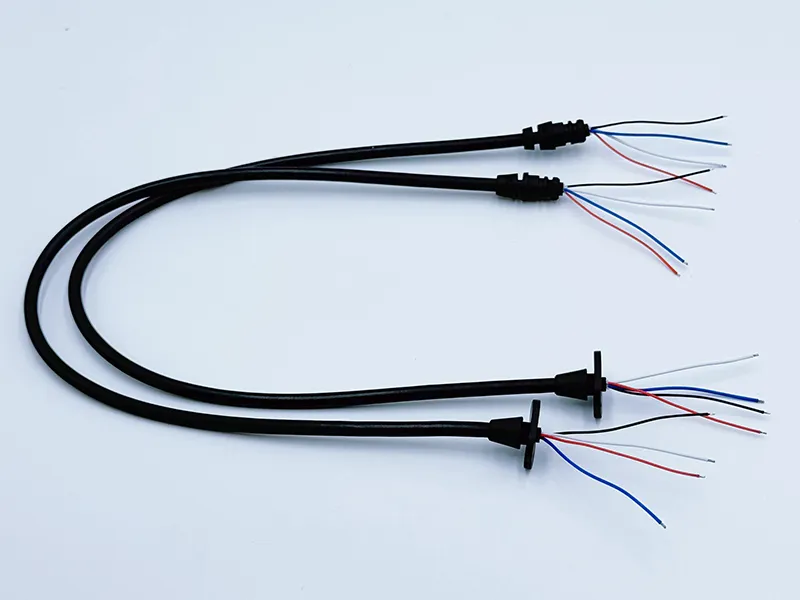

Wire harnesses (cable harnesses, or wiring harnesses) consist of organized wires, cables, or subcomponents and are designed to transmit power or signals. Harnesses can vary in complexity: simple harnesses have only a few components, whereas complex ones include multiple wires plus passive (e.g., resistors, connectors) and sometimes active (e.g., sensors or modules) components. Harnesses are structurally complex: each wire harness can extend into multiple branches, and each branch includes several terminals.

SAISONIC provides full customization services for harnesses, including various components and terminals. Our team looks forward to collaborating with you on your next breakthrough project! We will bring our extensive knowledge, design, and manufacturing expertise to help kick start your project.

(including but not limited to the following steps): Cutting, stripping, and identifying individual wires

- Crimping terminals onto one or both ends of the wire

- Routing wires and/or subassemblies through any required sleeves

- Partially inserting wires pre-crimped with terminals/contacts into connector housings

- Splice the wires and insulate them with tape, heat shrink tubing and sleeves

- Soldering wire ends

- Twisting wires

- Wire labeling and marking

- Testing

- Packing

-

Cutting

Cutting

-

Stripping

Stripping

-

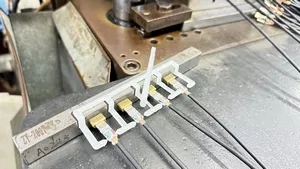

Crimping

Crimping

-

Connector installation

Connector installation

-

Assembly

Assembly

-

Soldering

Soldering

-

Injection molding

Injection molding

-

Inspection

Inspection

and wire harness manufacturing

SAISONIC uses advanced equipment to produce top-quality custom cable assemblies and wire harnesses. We offer valuable extra services, from custom wire labeling to wire cutting, giving our clients the best value and return on investment. Our advantages:

- Decades of knowledge and experience

- Use of only the highest-quality materials

- Consistent communication throughout the project

- Strict quality control standards and certifications

- Competitive pricing

If you have any questions, please feel free to contact us. We look forward to hearing from you. SAISONIC has extensive experience in manufacturing wire harnesses and cable assemblies for a wide range of industries.