Jumper Wires & Pre-Crimped Leads

Wires with pre-crimped terminalsSAISONIC controls quality during the production process of jumper wires using fully automated crimping machines for jumper wires and pre-crimped leads. We continuously monitor and record each crimped connection and its pull force in real time. This helps to ensure uniformity of the produced terminals, consistency of connection points, and prevents loose connections or broken wires. Our team reviews your designs and provides recommendations for terminal materials, process simplification, and structural optimization to improve efficiency and reduce BOM (Bill of Materials) costs.

We follow a “zero defects” approach and conduct full-process SPC (Statistical Process Control) to ensure product quality and uniformity regardless of production volume.

-

Cable length

Available in 1″ (2.5 cm), 2″ (5 cm), 3″ (7.5 cm), 6″ (15 cm), 12″ (30 cm), 24″ (60 cm), 36″ (90 cm), 60″ (150 cm), or customized as per request.

-

Color options

Black, brown, red, orange, yellow, green, blue, purple, gray, white, or customized as per request

- We produce terminals of various sizes, from miniature (0.13 mm²) to large (35 mm² and above), including flag terminals, ring terminals, spade terminals, male/female terminals, circular connectors, fork terminals, bullet terminals, ferrule terminals, butt connectors, flat blade terminals, and custom-special terminals. This allows us to manufacture wiring for both small electronics and heavy-duty industrial equipment.

- Our cable types include coaxial wires, twisted pair, shielded and unshielded cables, multi-core cables, and high-temperature Teflon wires. This range of cable types ensures compatibility with diverse electrical and mechanical requirements.

-

Precise Crimp Parameter Management

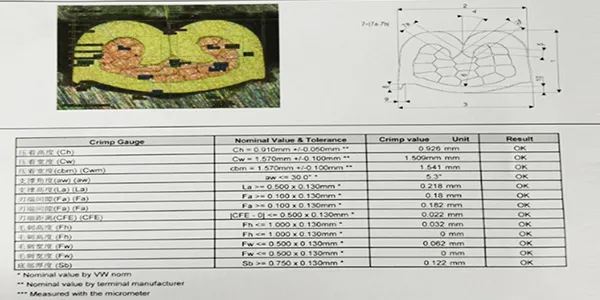

We create a separate, validated set of crimp parameters for each combination of wire and terminal, following manufacturer specifications and industry standards.

-

Fully Automated Crimping with Real-Time Monitoring

We use imported fully automated crimping machines equipped with CPK (Process Capability Index) real-time monitoring. This ensures that each crimp’s height and pull force are consistency monitored, and any out-of-tolerance crimp is automatically rejected with the alarm system activated.

Each crimp’s height, width, bell width, and support height are measured with advanced metallographic precision sectioning equipment and microscopes, then compared with standard charts.

-

Ring Terminal Pre-Crimped Wires

Ring Terminal Pre-Crimped Wires -

Ring Terminal Pre-Crimped Wires

Ring Terminal Pre-Crimped Wires -

Jumper Wires (with Heat Shrink Tubing)

Jumper Wires (with Heat Shrink Tubing) -

Pre-Crimped Wires

Pre-Crimped Wires -

Nylon-Braided Jumper Wires

Nylon-Braided Jumper Wires -

Bus-Bar Pre-Crimped Wires

Bus-Bar Pre-Crimped Wires -

Jumper Wires

Jumper Wires -

Jumper Wires with Fuse

Jumper Wires with Fuse

By choosing us as your crimped wire assembly manufacturer, you’re not just getting a custom wire harness assembly — you’re receiving a complete solution that integrates engineering expertise, advanced manufacturing technology, and a strong commitment to quality.

Pre-crimped wires are a type of wire with connectors or terminals already crimped. They are an ideal choice for prototyping and pre-production applications because they simplify wiring and installation. Pre-crimped wires can come with male or female crimped terminals, offering flexibility in routing and connectivity while saving assembly time.

There is a wide range of lengths, configurations, and styles of pre-crimped wires with connectors for any application. Common types of connectors used on pre-crimped wires include crimped sockets, crimped plugs, ferrules, insulated and non-insulated terminals, as well as specialized connector types for various electrical and mechanical requirements. This variety allows engineers to select the right wire and connector combination to meet specific system needs.

Pre-crimped wires are ideal for applications where stranded wires must be securely and accurately terminated. Compared to soldered or twisted wires, pre-crimped wires provide stronger and more reliable connections, maintain an airtight seal that prevents corrosion, and protect the wire strands from exposure to air and moisture. This ensures long-term durability and performance, especially in demanding environments.